| “Strategic Sourcing” is a term that has become popular in the supply management discipline. It has been | ||||||||||||||||||||||

| embraced by procurement professionals as being the state of the art “best practices” process. There is | ||||||||||||||||||||||

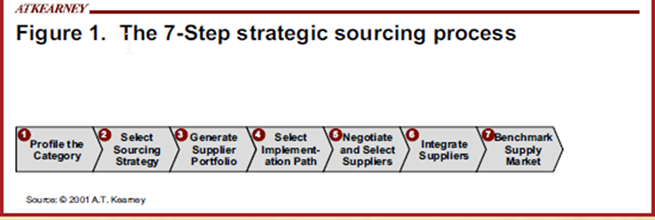

| some debate as to where the term arose. Many believe that the term was originated by A.T. Kearney for | ||||||||||||||||||||||

| their process. Some are generically known as Strategic Sourcing. Others are known by acronyms such as PLAN, MAP, STeP | ||||||||||||||||||||||

| The term "strategic sourcing" was popularized through work with a variety of blue chip companies by a number of consulting firms such as A.T. Kearney, Booz Allen Hamilton, KPMG, PricewaterhouseCoopers (bought PRTM), Partnering Group, IBM & Kramer Procurement Solutions in the late 80s and early 90s. This methodology has become the norm for procurement departments in large, sophisticated companies | ||||||||||||||||||||||

| Seven-Step Procurement Process: Kramer Procurement Solutions | ||||||||||||||||||||||

| Step 1. Strategic Planning; Negotiation as a Corporate Capability; Stakeholder Buy-in: | ||||||||||||||||||||||

| • Is your procurement project aligned with your strategic objectives? | ||||||||||||||||||||||

| • Do your buyers engage in negotiation training on a regular basis as a corporate capability? | ||||||||||||||||||||||

| Step 2. Due Diligence; Specifications; Inclusive Field of Suppliers: | ||||||||||||||||||||||

| • Do your buyers have the tools to gain intelligence on the supplier and the product or service to identify qualified suppliers and their interests? | ||||||||||||||||||||||

| • Have you defined your specifications to be unambiguous and complete? | ||||||||||||||||||||||

| Step 3. Request for Proposal (RFP); Minimum Contract Guidelines: | ||||||||||||||||||||||

| • Does your request for proposal allow your buyers to make an objective/weighted comparison and provide for a transparent process with suppliers? | ||||||||||||||||||||||

| Step 4. Weighted Supplier Scorecard; Multiple Rounds of Negotiations; Contract Execution: | ||||||||||||||||||||||

| • Do your buyers have the tools to facilitate multiple rounds of collaborative negotiations with suppliers? | ||||||||||||||||||||||

| • Do you have the tools to convert an agreed upon deal to a contract quickly and without adversarial negotiations? | ||||||||||||||||||||||

| Step 5. Contract Summary Database; Issue POs on Contract; Control Consumption: | ||||||||||||||||||||||

| • Do you have a simple way to communicate the rights and obligations of the negotiated deal with stakeholders? | ||||||||||||||||||||||

| • Does your process ensure that users procure products and services through the negotiated contracts as well as control their consumption? | ||||||||||||||||||||||

| Step 6. Audit Compliance with Quality, Delivery, Service, Inventory Control, and Price: | ||||||||||||||||||||||

| • Do you adequately audit volume purchased and quality standards against contract commitments? | ||||||||||||||||||||||

| Step 7. Supplier Relationship Management; Post-Mortem Review; Next Negotiation: | ||||||||||||||||||||||

| • Do your buyers conduct periodic evaluations of process and

build the supplier relationship – what have we learned?, what could we do better?, how do we respond better to feedback? |

||||||||||||||||||||||

| • Does your process have a built-in mechanism to tickle preparation and execution of the next bid on each product or service? | ||||||||||||||||||||||

| AT Kearney: | ||||||||||||||||||||||

|

||||||||||||||||||||||

| STEP 1 ) Analyze

category, spend & targets Here Procurement is looking to understand the total financial spend by defining the category (i.e. janitorial, security, facilities management, etc.), then quantifying spend in that category at all locations company wide. This guides their choice of strategy, which can provide greater purchase efficiencies and negotiation leverage. Procurement also seeks to understand the service needs of business owners (your customer contacts) and their end-users. Savings targets and performance baselines are identified for comparisons in later steps of the process |

||||||||||||||||||||||

| STEP 2 ) Select sourcing strategy Procurement has multiple sourcing strategies to choose from based on their analysis in Step 1. Here are 6 from A.T. Kearney, listed in no particular order: * Volume Concentration – you’ve seen this as large contracts that roll all locations and/or services into a single contract/supplier. * Specifications Improvement - re-scope or re-engineer service specifications for better, faster, cheaper. * Best Price – renegotiating based on breaking apart services and/or making profit “buckets” visible * Global Sourcing – seek new suppliers globally and/or develop new suppliers based on markets with high number of suppliers * Joint Process Improvement – this happens to some degree with facility services, its where the customer’s staff does part of a task/job and the supplier’s staff does the other part * Relationship Restructuring – relatively infrequent with facility services, this is where true strategic alliances and partnering occurs and where customers consider what they’ll make (in-house) vs. buy (outsource) |

||||||||||||||||||||||

| STEP 3 ) Generate supplier portfolio Procurement looks for potential suppliers, ones capable of delivering service as they understand it from Step 1 above. They’ll also include suppliers from their business owners (your customer contacts). That saves them some time in filling out a potential suppliers list. Procurement, together with business owners, will rough out supplier selection criteria and the evaluation process. Depending on the buy, Procurement may hold an Request for Information (RFI) to cull down suppliers to a pre-qualified manageable number. |

||||||||||||||||||||||

| STEP 4 ) Select Implementation path

(Hold RFP process, etc.) This is the part suppliers are most familiar with, the Request for Proposal (RFP). Procurement: sends out the RFP to pre-qualified suppliers a bid walk of locations takes place questions are answered & distributed to all bidders bid submittals are evaluated a short-list of suppliers make in-person presentations at last a decision is made NOTE: A negotiation phase takes place before the final decision is made. Procurement begins negotiations, often with the top 2 supplier finalists. This is insurance in the event Procurement can’t reach final agreement with their top choice. It also gives Procurement the chance to further negotiate price and/or terms with their top choice by having a backup in place as leverage. As an alternative to holding an RFP, or at the end of the RFP process, Procurement can still negotiate with the incumbent supplier, using the competitive bid data for better price and terms from the incumbent. |

||||||||||||||||||||||

| Step 5: Negotiate and select suppliers Many people dislike negotiating, but this fifth step of the strategic sourcing process is important and needs careful preparation. Start with putting together your negotiations team. Typical roles to include on a negotiations team are the spokesperson, a senior authority, a technical expert, a user, and an observer (note-taker). Certain team members may also play the “good guy” or the “bad guy.” If you operate a one-person information department, ask for support from someone in the finance or legal departments. You may even want to consider hiring a professional negotiator, if you are negotiating an extremely large and important contract and have little negotiations experience. Develop your negotiations strategy. Information is the key here and includes the information from your RFPs and your needs analysis, as well as knowledge of what is happening in the supplier marketplace and the suppliers’ likely bargaining stance. Understand your current bargaining position. What is your most desired outcome (MDO), your least acceptable agreement (LAA) and your best alternative to a negotiated agreement (BATNA)? What are your negotiating levers? |

||||||||||||||||||||||

| Step 6: Integrate suppliers If you have decided to work with a new supplier and/or to discontinue an old one, you will need to • Identify any transition issues (providing user details to the new supplier, for example) • Consider the organizational implications and any required changes • Create new processes and procedures if necessary (for example, how will charge-backs be handled?) • Create a transition/implementation plan • Communicate the changes to your users |

||||||||||||||||||||||

| Step 7: Monitor the supply market and

supplier performance Once your new agreement is in place, it’s time to start thinking about the next sourcing exercise. Plan ahead and stay abreast of your supply market conditions, so that next time your contract is up for renewal you’ve already done part of the groundwork. In your new contract, state performance metrics that you have agreed upon with your supplier, for example joint process improvements, quarterly meetings and monthly usage reports. What procedures will you put in place to monitor these on a regular basis, and how will you develop your relationship with the supplier so thatyou have a foundation to work from next time? |

||||||||||||||||||||||

| The IBM Institute for Business Value recommends a seven-step process for developing a strategic sourcing approach: | ||||||||||||||||||||||

| 1. Conduct spend analysis: Collect and analyze category baseline spend data and then identify potential opportunities and re-evaluate project scope. | ||||||||||||||||||||||

| 2. Determine business requirements: Assess current and future business needs, and challenge internal customer requirements to identify opportunities to reduce costs while enhancing quality and service. | ||||||||||||||||||||||

| 3. Conduct market analysis: Understand the supply market in order to form category strategies that match business requirements with supply market capabilities. | ||||||||||||||||||||||

| 4. Develop category strategy: Select the most appropriate market sourcing strategy for the category by identifying the potential strategic alternatives and analyzing each option. | ||||||||||||||||||||||

| 5. Select suppliers and negotiate: Provide a fair, consistent and structured approach to the identification, evaluation and qualification of suppliers, as well as the subsequent selection of suppliers that support business objectives. | ||||||||||||||||||||||

| 6. Develop implementation plan: Provide a structured approach to developing supply transition plans. | ||||||||||||||||||||||

| 7. Manage supplier performance: Maintain the performance of internal users and the supply base, the meeting of business requirements and contractual terms, the capture of savings and benefits, and the improvement of supply relationships. | ||||||||||||||||||||||

|

||||||||||||||||||||||

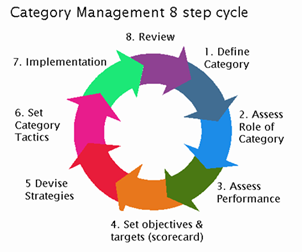

| The industry standard model for category management in retail is the 8-step process, or 8-step cycle developed by the Partnering Group. The eight steps are shown in the diagram on the right; they are : | ||||||||||||||||||||||

| 1) Define the category (i.e. what products are included/excluded). | ||||||||||||||||||||||

| 2) Define the role of the category within the retailer. | ||||||||||||||||||||||

| 3) Assess the current performance. | ||||||||||||||||||||||

| 4) Set objectives and targets for the category. | ||||||||||||||||||||||

| 5) Devise an overall Strategy. | ||||||||||||||||||||||

| 6) Devise specific tactics. | ||||||||||||||||||||||

| 7) Implementation. | ||||||||||||||||||||||

| 8) The eighth step is one of review which takes us back to step 1 | ||||||||||||||||||||||

| Strategic Contact | ||||||||||||||||||||||

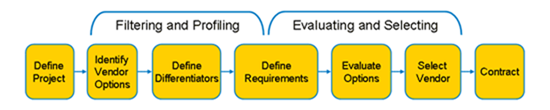

| Don’t short-circuit the contact center technology selection process with a blind request for proposal (RFP), a quick decision based on a team member’s experience at a previous employer, or an emotional attachment to a product or vendor! | ||||||||||||||||||||||

| Assemble a cross-functional team to conduct a requirements and evaluation process and perform appropriate due diligence. Invite call center leadership, analysts, and IT/telecom to join the team; include HR, legal, marketing and others as appropriate, based on the technology you’re pursuing. Then follow our 7 step process. | ||||||||||||||||||||||

|

||||||||||||||||||||||

| 1. Clearly define the goals and scope of the project in the context of your business strategy. | ||||||||||||||||||||||

| 2. Identify contact center technology options. Consider significant decisions such as buy versus build, customize versus configure, premises versus hosted versus managed services, and suite versus best-of-breed. | ||||||||||||||||||||||

| 3. Develop vendor profiles for products and services of interest. Focus on key features and functions that really matter to your business and/or clearly distinguish the vendors from one another. | ||||||||||||||||||||||

| 4. Use the differentiators that you established in the previous step to build a request for quote or proposal (RFQ or RFP) that defines functional, technical, vendor, implementation, support, and pricing requirements. | ||||||||||||||||||||||

| 5. Evaluate your call center technology options by reviewing vendor responses (proposal, configuration and quote), developing pros and cons, analyzing costs, and addressing questions. Conduct vendor demonstrations and presentations based on an agenda that you define carefully and control. | ||||||||||||||||||||||

| 6. Use a formal scorecard with criteria and weightings to select your vendor partner. It helps remove some of the emotional bias that inevitably enters into the decision process and creates the means for team members to identify and discuss specific areas in which there may be differences of opinion. Your recommendation to senior management needs to reflect a group consensus. | ||||||||||||||||||||||

| 7. Sign a contract with the vendor. Make sure to include service-level agreements (SLA) and a formal statement of work. Negotiation isn’t just about price and legal terms; it is about clearly establishing who will do what in terms of implementation and support and the results you can expect at every step | ||||||||||||||||||||||

| The seven stages of a sourcing strategy | ||||||||||||||||||||||

| A diagnostic of a company’s spend must first be undertaken. | ||||||||||||||||||||||

| Divide the total corporate spend into categories that relate to the supplier markets, and then further divide spend categories by business units or locations to identify each supplier. | ||||||||||||||||||||||

| This initial diagnostic is required to be only around 80 per cent accurate to have relevance and to offer valuable insight. | ||||||||||||||||||||||

| If and when sourcing teams need to refine spend data for each category, the supplier may be a more accurate source. This is discussed further below. | ||||||||||||||||||||||

| Diagnostics can provide a spend map by category. These spend categories should be classified according to competitiveness in the supplier marketplace compared with how important they are to the organisation. This results in a spend category matrix that will help direct the team towards a potential sourcing strategy for each category. | ||||||||||||||||||||||

| The Kraljic portfolio purchasing model plots categories as strategic (low supply market competitiveness, high business impact); leverage (high supply market competitiveness, high business impact); bottleneck (low supply market competitiveness, low business impact); and routine (high supply market competitiveness, low business impact). (See matrix below.) | ||||||||||||||||||||||

| Once diagnostics are complete, the business must decide which categories to address immediately and which to delay until internal or external conditions are better. For those categories that need immediate attention, the seven-step process begins. | ||||||||||||||||||||||

| Step One – Fully understand the spend category | ||||||||||||||||||||||

| This step, along with the next two, is conducted by the sourcing team. At this stage, the team needs to ensure it understands everything about the spend category itself. For example, if the category is corrugated packaging at a consumer products company, the team will need to understand the definition of the category, usage patterns and why the particular types and grades were specified. | ||||||||||||||||||||||

| Stakeholders at all operating units and physical locations would need to be identified. For example logistics, which may need to know about shipping specifications, or marketing, which may need to understand certain quality or environmental characteristics, where applicable. | ||||||||||||||||||||||

| The five key areas of analysis are: | ||||||||||||||||||||||

| • Total historic expenditure and volumes; | ||||||||||||||||||||||

| • Expenditure categorised by commodity and sub-commodity; | ||||||||||||||||||||||

| • Expenditure by division, department or user; | ||||||||||||||||||||||

| • Expenditure by supplier; | ||||||||||||||||||||||

| • Future demand projections or budgets. | ||||||||||||||||||||||

| Step Two – Supplier market assessment | ||||||||||||||||||||||

| Concurrently run supplier market assessment for seeking alternative suppliers to existing incumbents. Understand the key supplier marketplace dynamics and current trends. Prepare ‘should-cost’ information from the major components of the key products. Take a view on the key suppliers’ sub-tier marketplace, and analyse for any risks as well as opportunities. | ||||||||||||||||||||||

| Should-cost analysis is not appropriate for every item. In many cases, traditional strategic sourcing techniques work well. But in those cases where strategic sourcing cannot be applied, should-cost analysis provides a valuable tool that can drive cost reductions and supplier continuous improvement efforts. | ||||||||||||||||||||||

| Step Three – Prepare a supplier survey | ||||||||||||||||||||||

| Next, develop a supplier survey for both incumbent and potential alternative suppliers. This survey will help evaluate the supplier capabilities. At this point, consider verifying spend information using data that incumbent suppliers have from their sales systems. | ||||||||||||||||||||||

| The survey is to assess the capability and capacity of the market to meet your requirements. It enables you to assess at an early stage whether your proposed project is feasible and can be delivered by the identified supply base. It also provides an early warning of your requirements to the market, and enables suppliers to think about how they will respond. The key aim here is to encourage the right suppliers with the right structure to respond to you. | ||||||||||||||||||||||

| Look to gather knowledge in these key areas: | ||||||||||||||||||||||

| • feasibility | ||||||||||||||||||||||

| • capability | ||||||||||||||||||||||

| • maturity | ||||||||||||||||||||||

| • capacity | ||||||||||||||||||||||

| Step Four – Building the strategy | ||||||||||||||||||||||

| This step involves developing the sourcing strategy. The combination of the first three steps provides the essential ingredients for the sourcing strategy. However, for each area or category it will depend on: | ||||||||||||||||||||||

| 1. How competitive the supplier marketplace is | ||||||||||||||||||||||

| Armed with the supplier information, you can build the competitive landscape in the supply marketplace. This can help demonstrate the ‘size of the prize’ to alternative suppliers, and communicates the seriousness of a potential sourcing exercise to incumbent suppliers. | ||||||||||||||||||||||

| 2. How supportive your organisation’s users are to testing incumbent supplier relationships | ||||||||||||||||||||||

| A sourcing team has two sets of internal stakeholders: the people who use the things that are bought, and the executives who manage overall costs. The people who consume the spend category will accept cost reductions as long as the process is: started in another department; doesn’t mean a change in suppliers; and doesn’t jeopardise a good relationship with the supply base, generate complaints or affect issues such as delivery reliability, service or payments. | ||||||||||||||||||||||

| For executives, cost and service competitiveness is a key objective, but they too are users of various corporate services, so are often caught between the pursuit of cost improvement and a user mentality of resisting change. To mobilise users’ and executives’ support for the category sourcing strategy, it is vital to communicate all the benefits and overcome any potential risks. | ||||||||||||||||||||||

| 3. What alternatives exist to competitive assessment | ||||||||||||||||||||||

| If the supply base is competitive, you can harness those forces to leverage better pricing or terms owing to increased volume of a streamlined product specification. Once the result of the competitive sourcing effort is determined, it will be useful to set up a collaborative programme that will run until the next competitive sourcing event takes place. | ||||||||||||||||||||||

| If a competitive approach to sourcing isn’t a viable option, it’s worth considering what the alternatives are, such as collaborating with suppliers: | ||||||||||||||||||||||

| • to reduce complexity and in turn increase productivity; | ||||||||||||||||||||||

| • to create corroborative process improvements that reduce the cost of doing business; | ||||||||||||||||||||||

| • to change the way the relationship is structured. For example, firms may invest in supplier operations to guarantee access to supply, new technology or process improvements. | ||||||||||||||||||||||

| These alternatives are pursued typically when a buying company has little leverage over its supply base. They will be relying on good faith that suppliers will share the benefits of a new approach. | ||||||||||||||||||||||

| The sourcing strategy is an accumulation of all the drivers thus far mentioned. | ||||||||||||||||||||||

| Step Five – RFx Request for… | ||||||||||||||||||||||

| Where a competitive approach is used, which is the general case for most spend categories, a request for proposal or bid will need to be prepared (RFP, RFQs, eRFQs, ITTs). This will define and make clear the requirements to all prequalified suppliers. It should include product or service specifications, delivery and service requirements, evaluation criteria, pricing structure, and financial terms and conditions. A communication plan should also be implemented at this stage to attract maximum supplier interest. Ensure that every supplier is aware they are competing on a level | ||||||||||||||||||||||

| playing field. | ||||||||||||||||||||||

| Once the RFP is sent out to all suppliers, make sure they are given enough time to respond. Follow-up messages should also be sent out to encourage a greater response. | ||||||||||||||||||||||

| Step Six – Selection | ||||||||||||||||||||||

| This is about selecting and negotiating with suppliers. The sourcing team should apply its evaluation criteria to the supplier responses. If extra information beyond the RFP response is required, don’t be afraid to ask for it. If carried out manually, the negotiation process is conducted first with a larger set of suppliers, then narrowed to a few finalists. If the sourcing team uses an electronic negotiation tool, a greater number of suppliers may be kept in the process for longer, giving more diverse suppliers a better chance at winning the business. | ||||||||||||||||||||||

| Compare outcomes in terms of total value or implementation cost differences. Departments directly affected can be brought into the final selection process. Senior executives should be briefed on the final selection, to gain their approval and also be given the rationale behind the decision, to prepare them for any calls they receive from disappointed suppliers. | ||||||||||||||||||||||

| Step Seven – Communicate with your new suppliers | ||||||||||||||||||||||

| Once the winning supplier(s) are notified they should be invited to participate in implementing recommendations. Implementation plans vary depending on the degree of supplier switches. For incumbents, there will be a communication plan that will include any changes in specifications, improvements in delivery, and service or pricing models. These ought to be communicated to users as well. Since the company may have significantly benefited from this entire process, it’s important that this be recognised by both company and supplier. | ||||||||||||||||||||||

| For new suppliers, a communication plan has to be developed that manages the transition from old to new at every point in the process that is touched by the spend category. Department, finance and customer service are affected by this change, and their risk antennae will be particularly sensitive during this period. It is particularly important to measure closely the new supplier’s performance during the first weeks of performance. | ||||||||||||||||||||||

| Being able to demonstrate that performance matches, or is superior to, that of the former supplier will be vital during this sensitive time. | ||||||||||||||||||||||

| It is also important to capture the intellectual capital your sourcing team has developed during the seven-step process so it can be used the next time that category is sourced. | ||||||||||||||||||||||